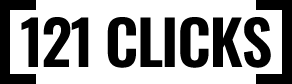

3D wooden puzzles are a unique combination of art, engineering and craftsmanship. They are not only a source of entertainment, but also a way to develop motor skills, spatial reasoning and creative skills.

Design Process

The design process for Wood Model Kits begins with a creative idea, which can come from a variety of sources of inspiration. Designers can draw ideas from nature, architecture, historical events, popular culture, or even abstract concepts. This initial stage requires not only creativity, but also a deep understanding of how different elements can be combined into a cohesive whole.

Once the idea is defined, the next step is to develop specific designs and drawings. This involves careful planning of every aspect of the puzzle, from the size and shape of each individual piece to how they will fit together in the finished product. It is important to consider not only aesthetics, but also functionality – for example, how easy or difficult the puzzle will be to assemble, and how strong the connections between the pieces will be.

At the design stage, designers often use specialized software to create three-dimensional models of puzzles. This allows them to visualize the final product and conduct virtual tests of the strength and fit of the pieces.

Choice of Materials

Not any wood is used for manufacturing, but specific species. These include:

- Birch

- Maple

- Walnut

These species of wood differ not only in their appearance and texture, but also in strength, which is critical for the durability of the puzzle. The choice of thickness and quality of wood depends on the anticipated complexity and size of the finished puzzle. For small and complex elements, thinner and lighter materials are chosen.

Production Process

Production consists of several important stages:

- Laser cutting. It is used for high-precision cutting of puzzle parts. This method allows you to create complex and precise shapes, which is ideal for 3D puzzles.

- Sanding. Each piece is carefully sanded after cutting. This is to ensure the surface is smooth and safe to use.

- Machining and coloring. The final stage of production involves treating the pieces with varnish or paint. This not only protects the wood, but also gives the puzzles a finished and attractive appearance.

After manufacturing, the puzzle pieces undergo a thorough quality control process. This ensures that each piece fits perfectly with the others, ensuring smooth assembly and accurate construction. The finished puzzles are packaged along with assembly instructions and shipped for sale.

Related Articles:

- From Flat to Fabulous: The Evolution of Traditional Puzzles into 3D Wooden Masterpieces

- Japanese Artist Nikichi Creates Beautiful And Poetic Animal Wooden Sculptures

- Artist Bruno Catalano Creates Otherworldly Sculptures Of Fragmented Travelers

- Spanish Artist Carlos Cabo Creates Amazing Abstract Figurative Ceramic Sculptures